Description

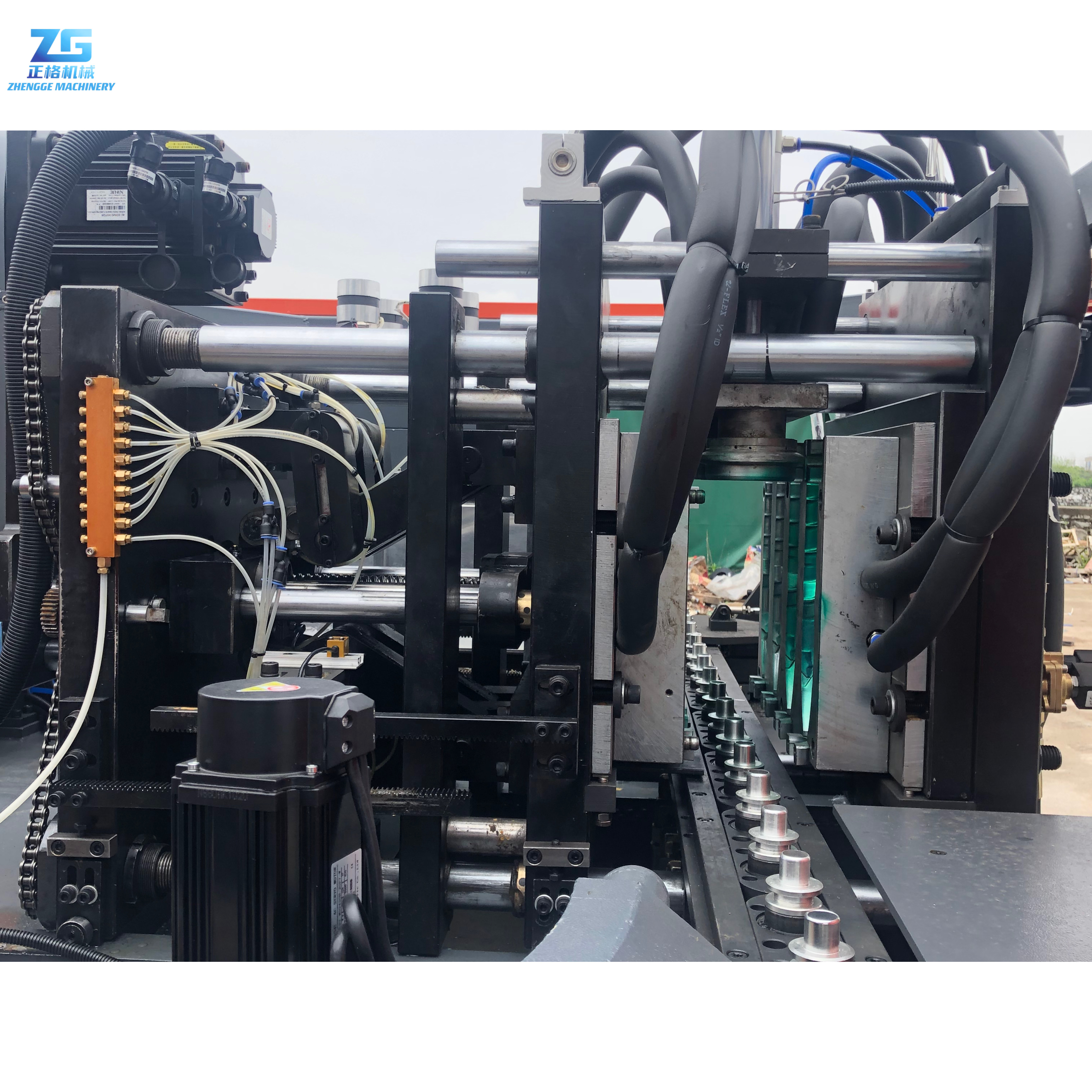

2020 Taizhou Manufacture Plastic Bottle Blowing Large Barrel Making Machine

– Machine Feature –

1). Stable performance with advanced PLC.

2). Automatic preform conveyor to save human cost.

3). Preform self-rotation and infrared pre-heater revolution assure the even distribution of heat, which improve the bottle shaping rate, increase the production.

4). High adjusting performance to enable preheat the preforms perfectly by adjust the voltage control area in the PLC, which could adjust the temperature of the infrared lights in the pre-heater, and keep the proper temperature and humidity invariable.

5). High safeties with security automatic-locking device in each mechanical action, which will make the production into a perfect safe environment, in case of the breakdown in certain procedure.

6). Satisfaction with different atmospheric pressure for blowing and mechanical action by dividing the blowing and action into three parts in the air pressure diagram of the machine.

7. Strong clamping force with high pressure and double crank links to lock the mould.

8). Safe,reliable and unique design of the position of valve to make the pneumatic diagram in the machine easier to understand.

9). Low cost,high efficiency,easy operation and maintenance etc, profited from the fully automatic technological process.

|

Automatic Bottle Blow Molding Machine

|

||||||

|

Main Machine

|

size

|

3700*2050*2200mm

|

||||

|

weight

|

4000kg

|

|||||

|

Preform Loader |

size

|

2000*1350*2550mm

|

||||

|

weight

|

550kg

|

|||||

|

Container Volume

|

max.20L

|

|||||

|

Preform Inner Diameter

|

65mm

|

|||||

|

Max.bottle Diameter

|

360mm

|

|||||

|

Max.bottle Height

|

520mm

|

|||||

|

Max.heating Power

|

30kw

|

|||||

|

Installation Power

|

75kw

|

|||||

|

Cavity

|

1cavity

|

|||||

Great Overall Performance

Simple and generous appearance designed by our senior engineers .Also can add logo and other designby customized.

Smart System

With the efforts of our engineers, now we can start our machine easily Which means you will have no trouble to operated when you get it.

Easy to Maintain

Don’t worry about machine maintain, we have optimize its structure, so now it is easy to maintain! Professional after sales service will be offered.

PLC Control systerm

smarts system

Temperature control

Preform loader

clamping noise.

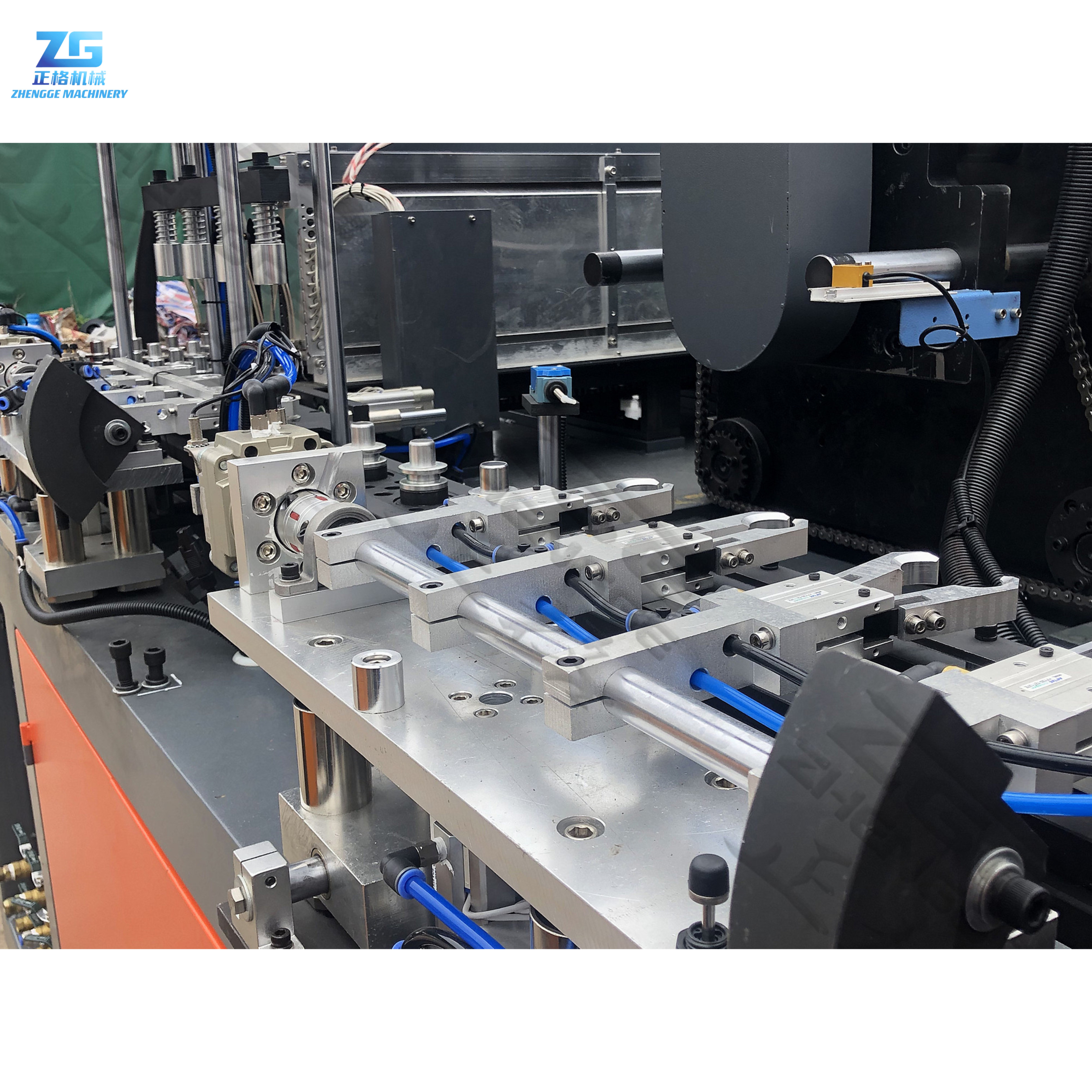

Manipulator

Manipulator controlled by PLC can take the finished bottle from the conveyor belt accuracy.

Cooperate closely,High accuracy.

Electrical components

*Adopt famous brand such as Schneider,

What we can do for bottle?

All bottle shape and bottle size we can do! We have a professional

engineer team.All bottle parameter can be customized by your need. We also can help

you optimized bottle design and supply the best solution for you!

ACHIEVE MEASURABLE RESULT

-Up to 45% less by heating

In our blower, preform distance is only 38mm, with fewer lamps, you can heat more preforms

-Up to 20 mins change mold

What if you change mold like open & close a drawer?

With our special quick-mold-change design, mold can find position itself. and be changed within 20 minutes

-Up to 30% less by air

This machine is fully driven by servo motor, no need low pressure air

We also decrease the dead volume in the blowing station to reduce high pressure air consumption

-Up to 80% less maintain cost

Changing new air cylinders and seal rings is main maintain cost in blower

We adopt servo motors, It is more reliable and almost no need maintain cost

Delivery&Package

Delivery time: 40 days as usual after confirm the bottle design.

Package way:The normal package is wooden box. If export to Europe countries,the wooden box will be fumigated.If container is too tight,we will use pe film for packing or pack it according to customers special request.

Pre-Sales Service

* Welcome to visiting our Factory.

*24 hours on line answer your question.

*According customers’ demands,recommending the most suitable machine.

* Take video to show real scenes as client’s request.

After-sale Service

*If you have any questions when use machine,please contact us, we will help you handle in time.

* Engineers available to service machinery overseas.

* We provide useful documents with machine.

* All spare parts are always available and free for your request in first year.

– Certificates –

– Introduction –

TAIZHOU HUANGYAN ZHENGGE PLASTIC MACHINERY CO,.LTD is specialized in manufacturing bottle blowing machine and mold.we have strong technical force, excellent production equipment,advanced testing instruments and perfect management system. The product will make your enterprise have a good progress day by day. TAIZHOU HUANGYAN ZHENGGE PLASTIC MACHINERY CO,.LTD. enjoys good reputation from regular and new customers through our excellent quality,competitive price production equipment, which attracts many customers to purchase.

– With Customers –

Expecting your visiting!!!

Reviews

There are no reviews yet.