Description

Product Description

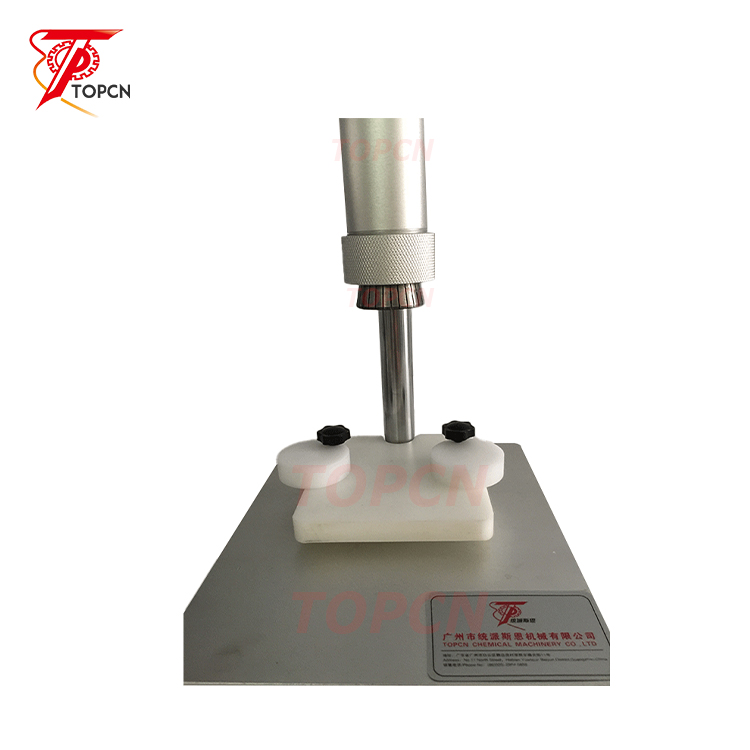

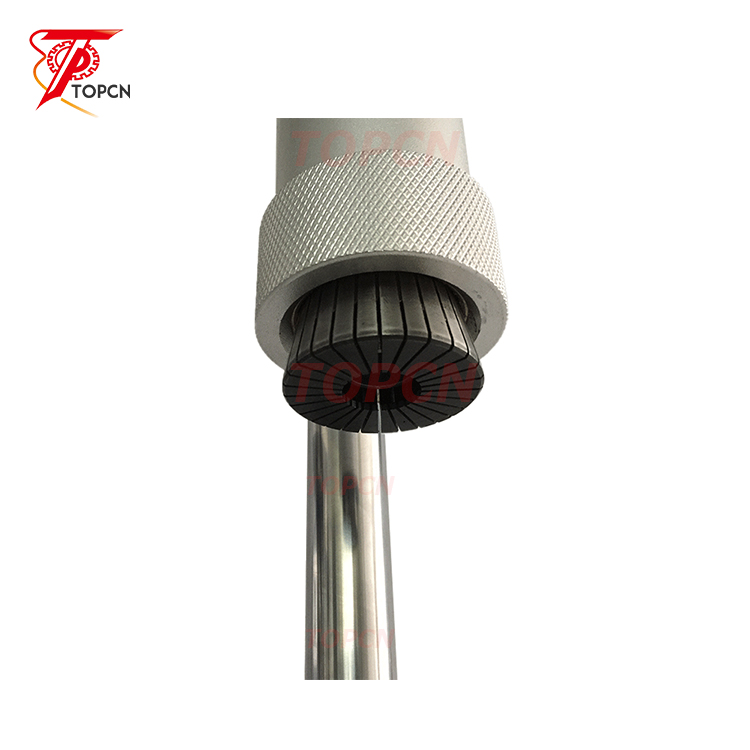

Using method: 1.put on the upper cover, put bottle into the rolling head, 2.gently press the handle until the rolling head is tightening(not too hard), release the handle to the original position. 3. Check the cap is loose or not, using three fingers. if not tight enough or not smooth enough, adjust the rolling head, clockwise to loose, anticlockwise to tighten. Product features: 1.Independent research, mature product, has been exported to Indonesia, France and other countries which require more perfume bottle types, reach a cooperative relationship between supply and demand. 2. Fixed part can be adjusted, suitable for a variety of perfume bottle types. 3. No electricity, pure manual operation, no complicated process, no maintenance troubles, highly adjustable, special bottle type can be customized. 4.High production efficiency, cost average 1-3 seconds to complete a work flow, simple operation, convenient maintenance, portable machine. 5.The introduction of the whole design is beautiful, generous, weight less than 8kg.

Specification

|

Product Size

|

250mm*210mm*550mm

|

|

Product Weight

|

7.5kg

|

|

Working Capacity

|

5-30times/min

|

|

application sprayer size

|

Fea12/Fea13/Fea15/Fea18/Fea20/Customized

|

Bottle position fix and adjust fixed bottle position and sealing accurately

Well processed R shape for all four sides of square crimping head body, bottle hold Teflon base and main machine base.

the handle is thread with bar, make them to be tightly connected

Steel mould is made of steel material, good sealing effect and no leakage

When press handle to crimping, spring buffer base ensure bottle will not damaged

Reviews

There are no reviews yet.